Technical characteristics

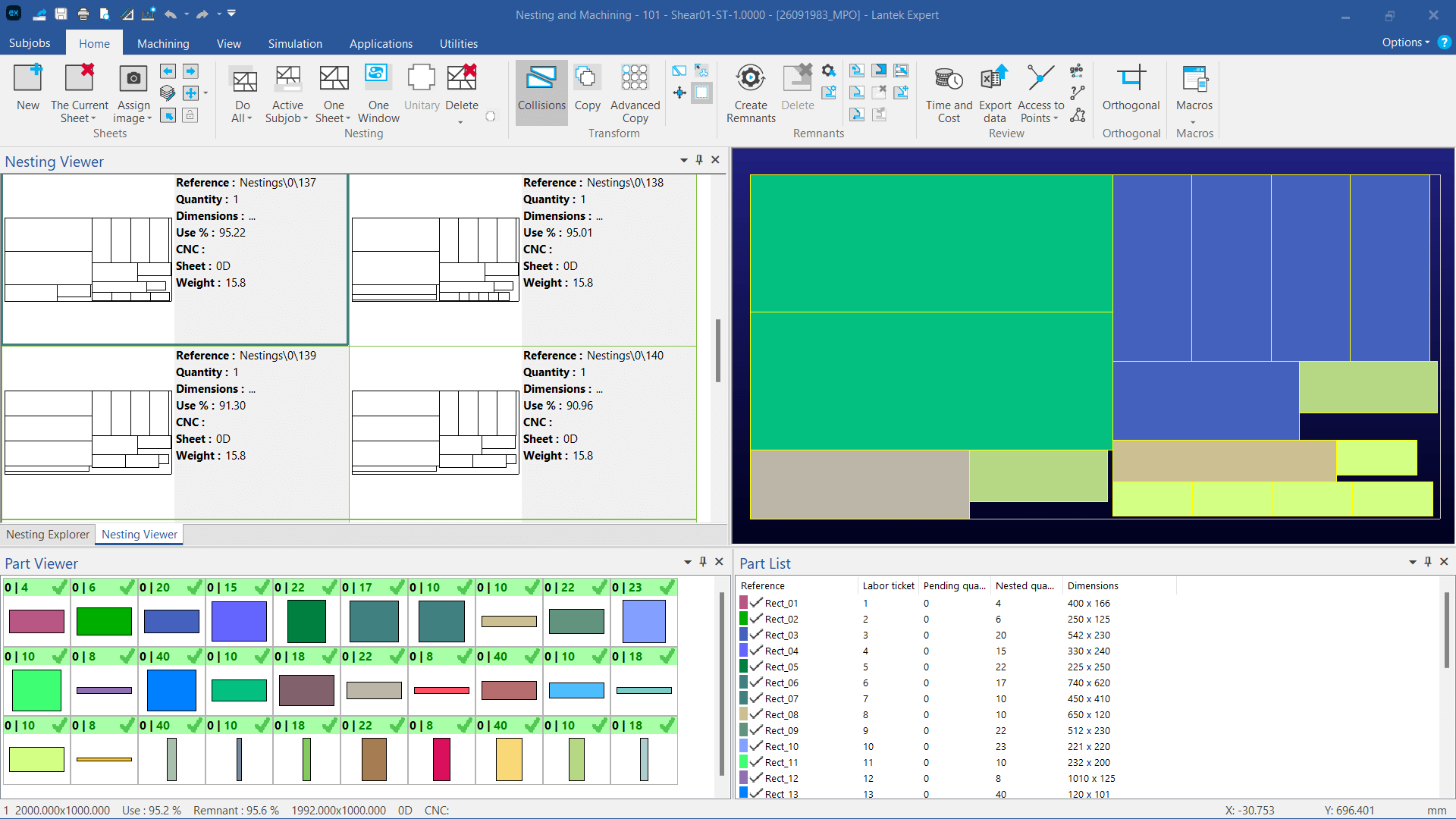

- This system allows high production levels to be achieved with substantial savings on materials.

- It´s a highly useful tool for calculating the material that will be needed for the production run, and is thus of incalculable value for the supply departments.

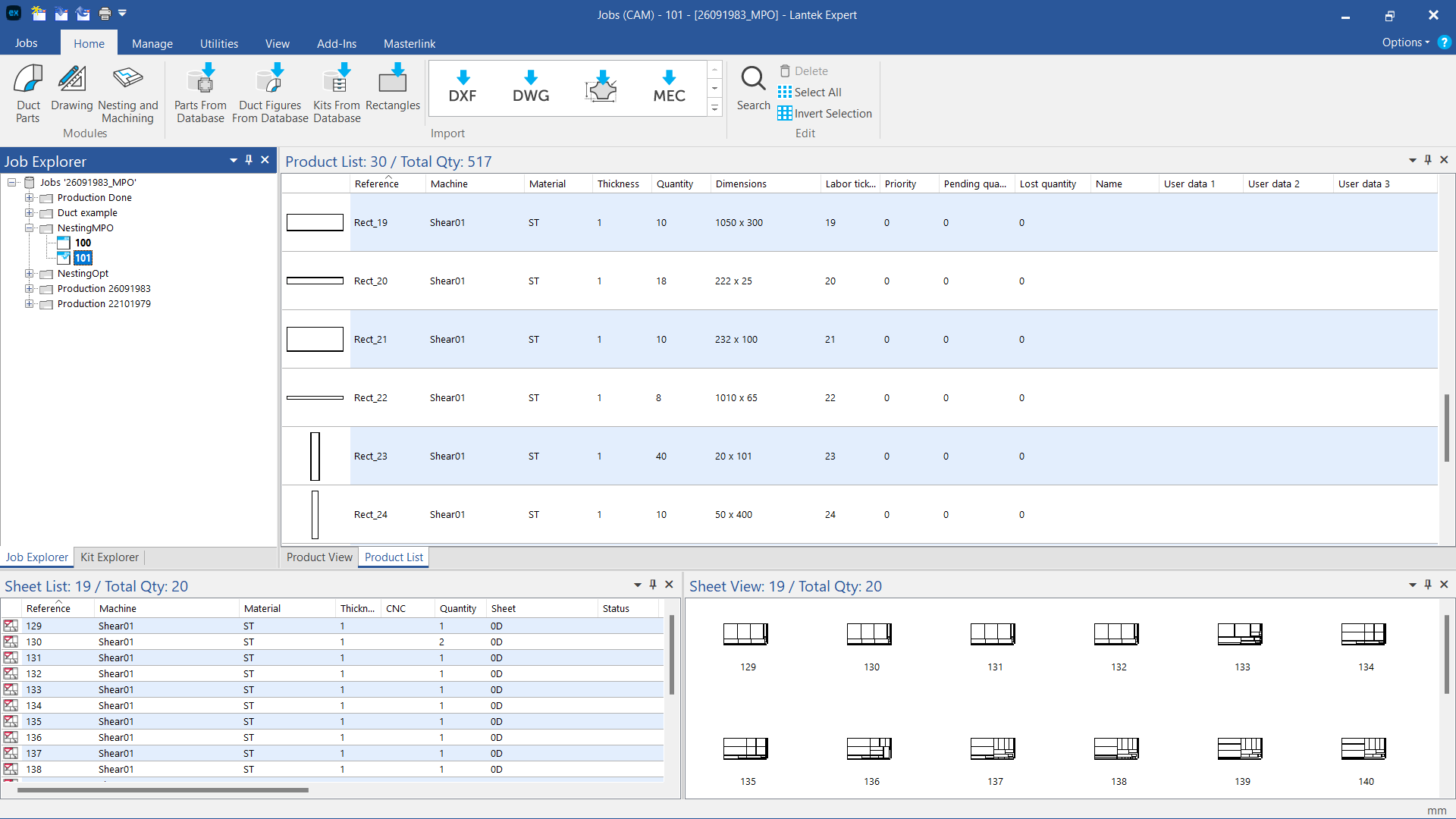

- Automatic optimization of fabrication orders in multiple sheets. Lantek Expert Quattro minimizes the required number of different sheet formats.

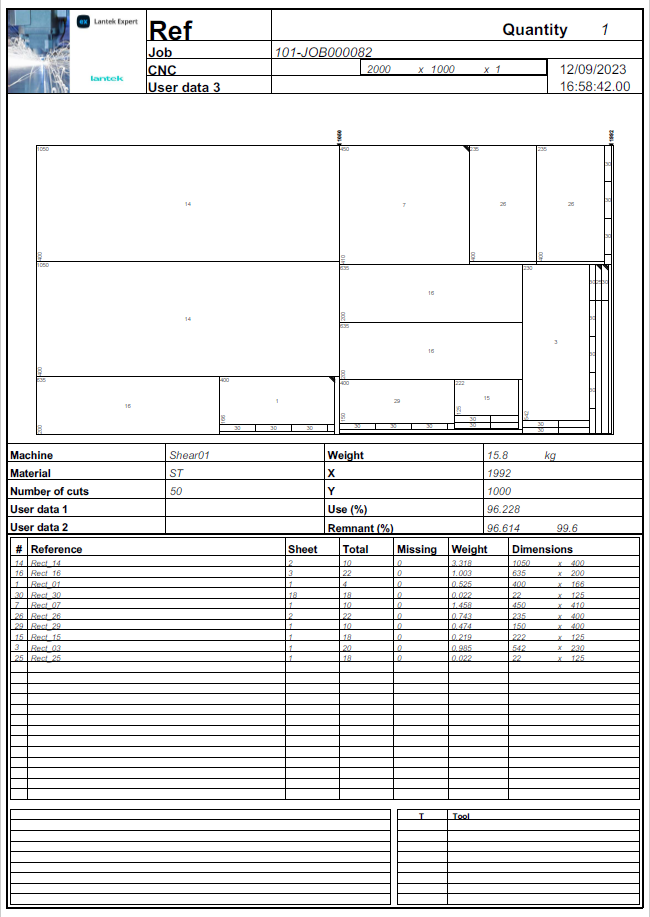

- Final results are shown on the screen and printed out: printout of nests, parts list, used sheets list.

- Results can be modified interacting with different configurable parameters according to the customer´s way of work.

- Sheet stock management, control of actual sheet stocks and automatic update of the stock whenever sheets are used by the system.

- Interface to import parts from other system (i.e. DXF) and even from MRP programs (optional).

1.jpg)