Easy to Use

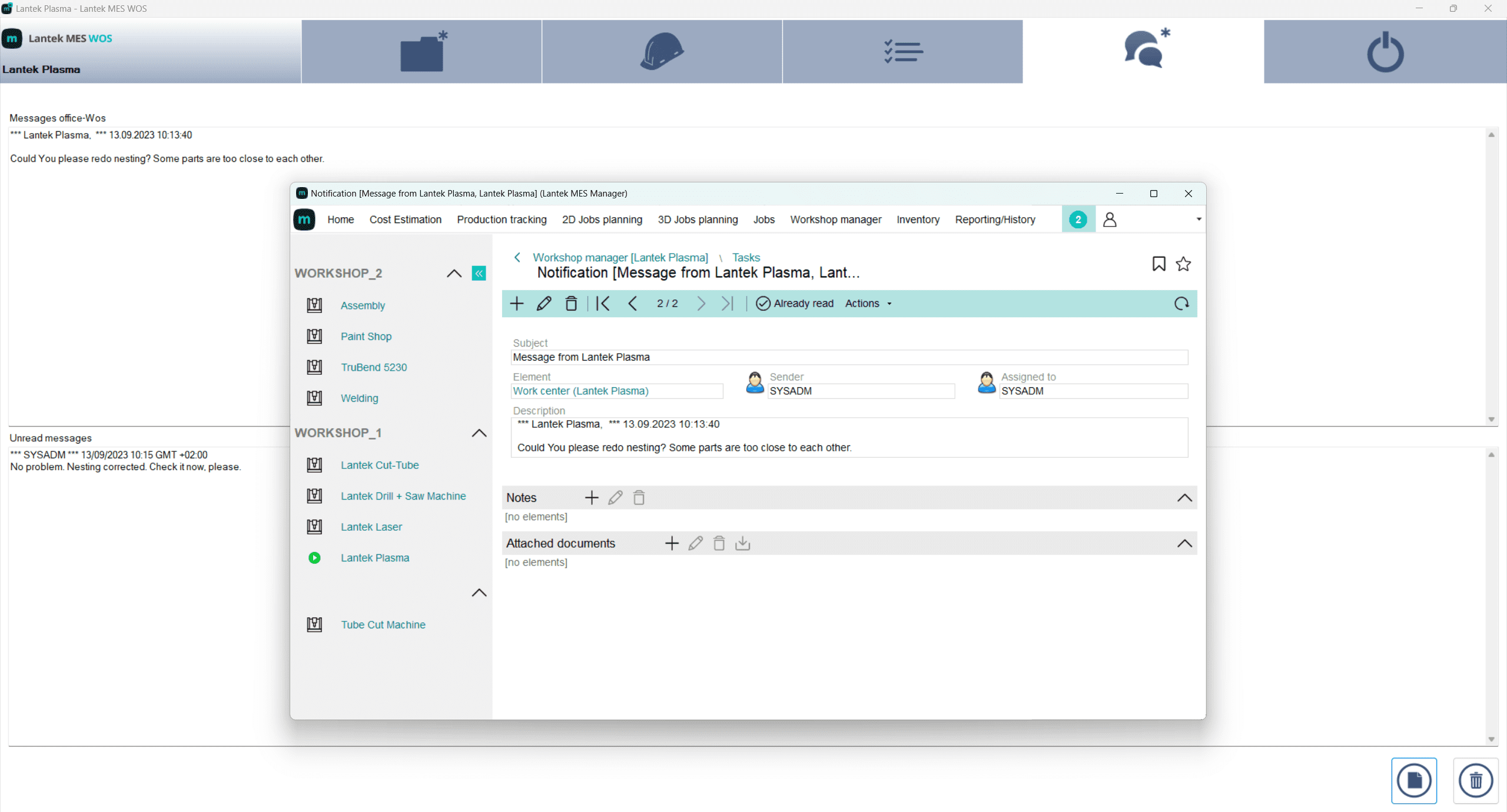

The main goal of Lantek MES Wos is to provide an easy to use and efficient solution for workshop data input. With intuitive screens and a minimal need for data entry, information is clear.

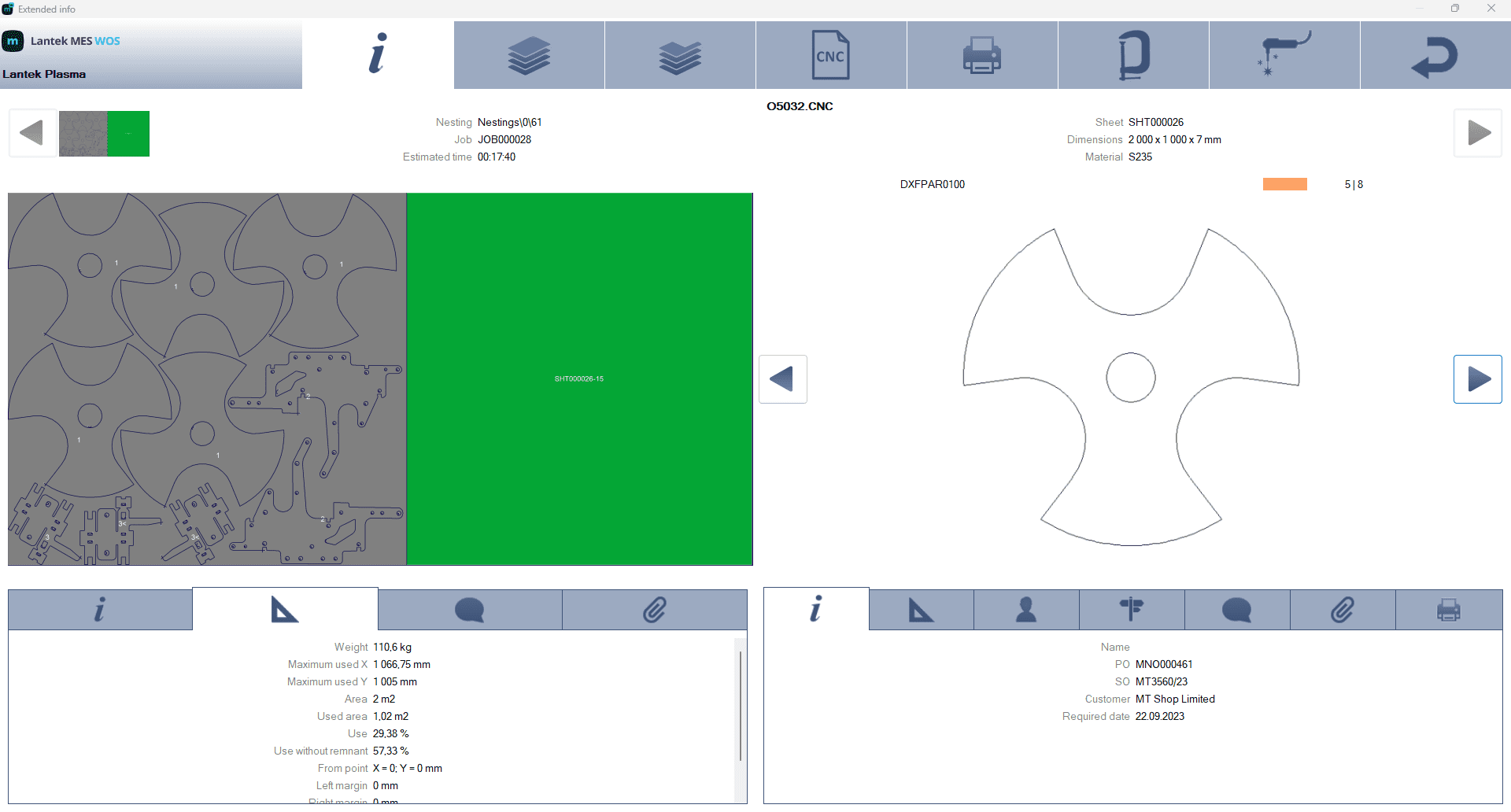

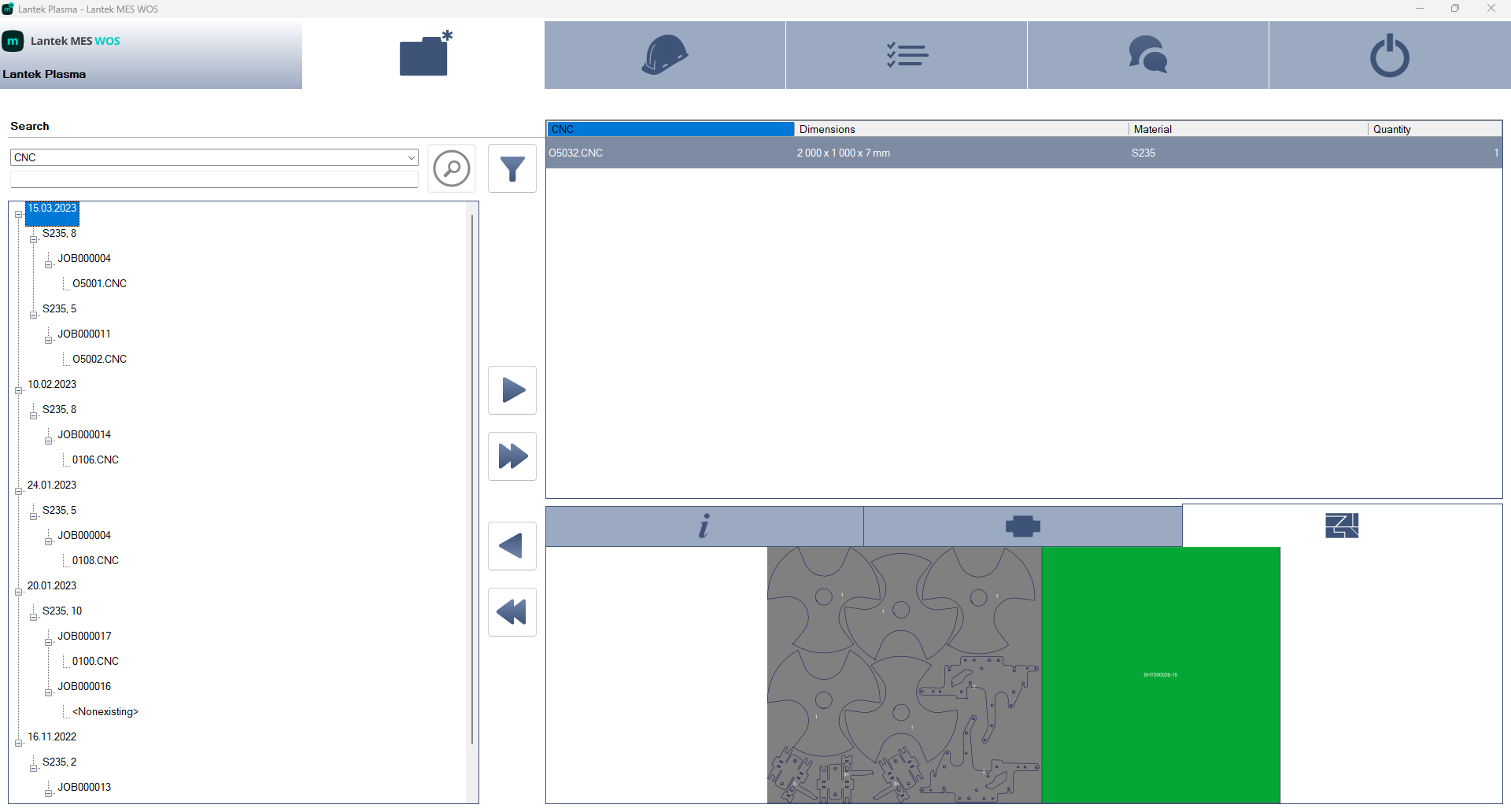

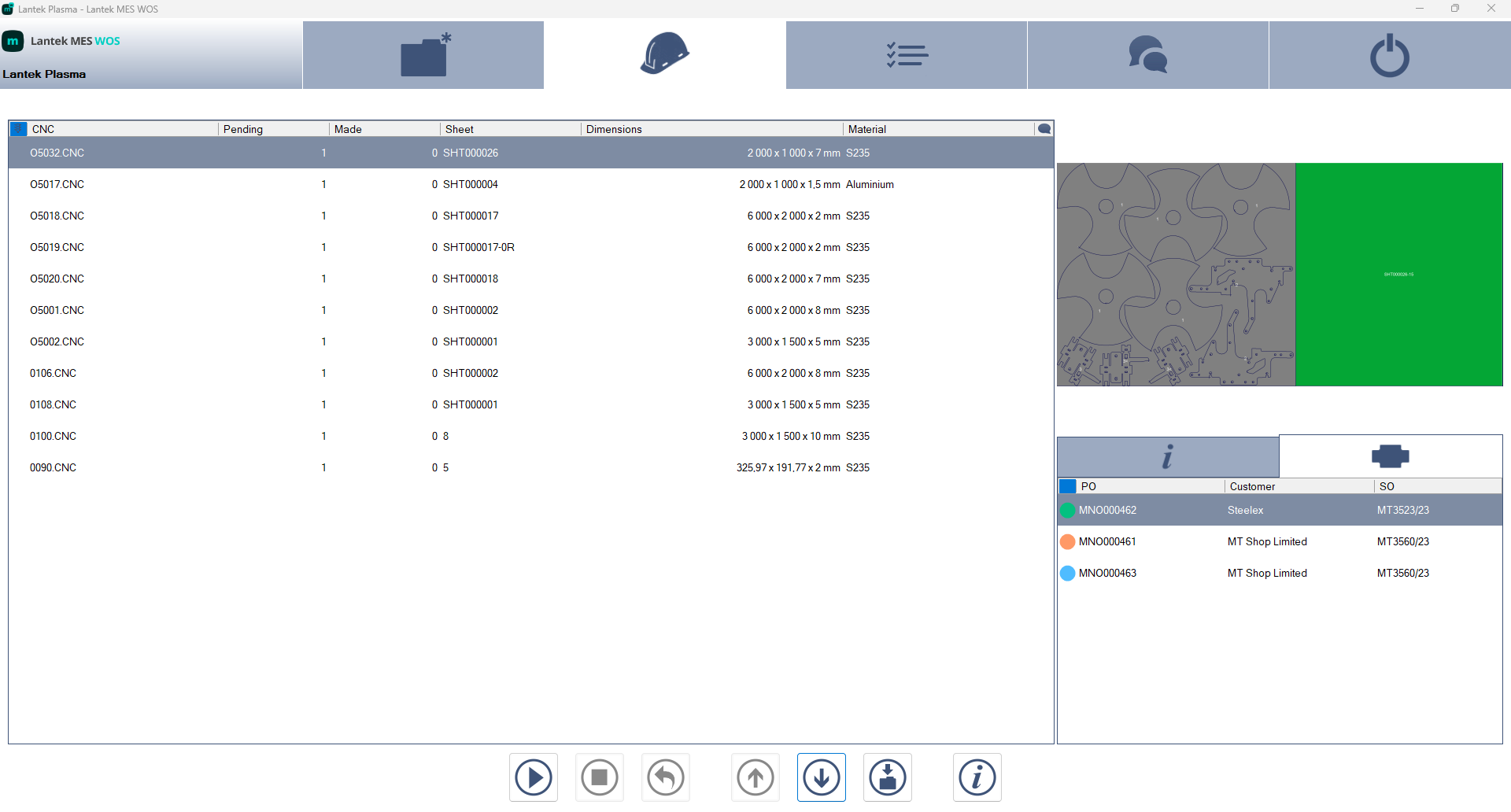

Lantek MES Wos includes multiple options that are associated with nesting and manufacturing operations for full display of information. To list a few options:

- 2D nest design

- The ability to re-order the sequence of jobs

- Numerical control (CNC) of the nests

- Users may check each of the parts that comprise the nest and their quantity, length, height, related order, etc.

- Process and machine times

- Graphic and intuitive displays of operations and nests status

.jpg)